Our eApps for your business success

Industry 4.0-Platform Tomorrow Connect

Tomorrow Connect collects and processes machine and sensor data automatically, and visualizes this with the help of eApps. The interaction between humans and machines and cyber-physical systems occurs within eApps from our eApps Store.

All eApps work on PCs as well as handheld devices, making them accessible with proper authorization at any time or place. The system is as easy to operate as adding apps on your smartphone.

After downloading/setting up Tomorrow Connect, you will gain access to the eApps4Production Store, where you can select your desired eApps.

eApp Tomorrow Connect live

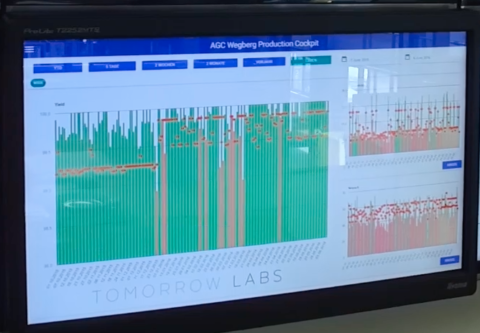

eApp Production Cockpit

eApp Excel Add-In

eApp Downtime-Tracker

eApp Maintenance (coming soon)

ERP Integration

Software Development Kit (SDK)

Tomorrow Labs Connector

Data Collection